The LED lighting industry is currently pushing levels of innovation hitherto unheard of. The advancements within the LED world is enabling lighting designers and manufacturers to come up with state-of-the-art lighting systems and luminaires.

But, wait! Like every other happening thing in the market, there's a catch here as well. Trying to jump on to the LED bandwagon and reap the benefits without having a thorough understanding of the nuances can be fatal for your business.

Here are some major oversights that OEMs should be aware of to ensure that your business stays sustainable.

1. Buying from Unknown Sources

All that glitters is not gold. This is especially true when it comes to the LED industry. In the chase for better prices, settling for cheaper variants of the same product can lead to inevitable repair/maintenance/replacement costs in the future, thus rendering your product incapable of a long lifetime.

There are several manufacturers who churn out LED components and drivers as well as various other related components to suit different specifications. But there is a considerable difference in products originating from recognized sources as the package includes better lifetime and warranty. The issue of fake parts is also rampant with Havocscope noting that counterfeit parts cause losses amounting to nearly $169 billion each year!

Despite the price differences, authentic products can significantly enhance the quality of your product which would come in handy during the long run and build a reputation for your products in the market.

2. Being Unaware of the Supply Chain

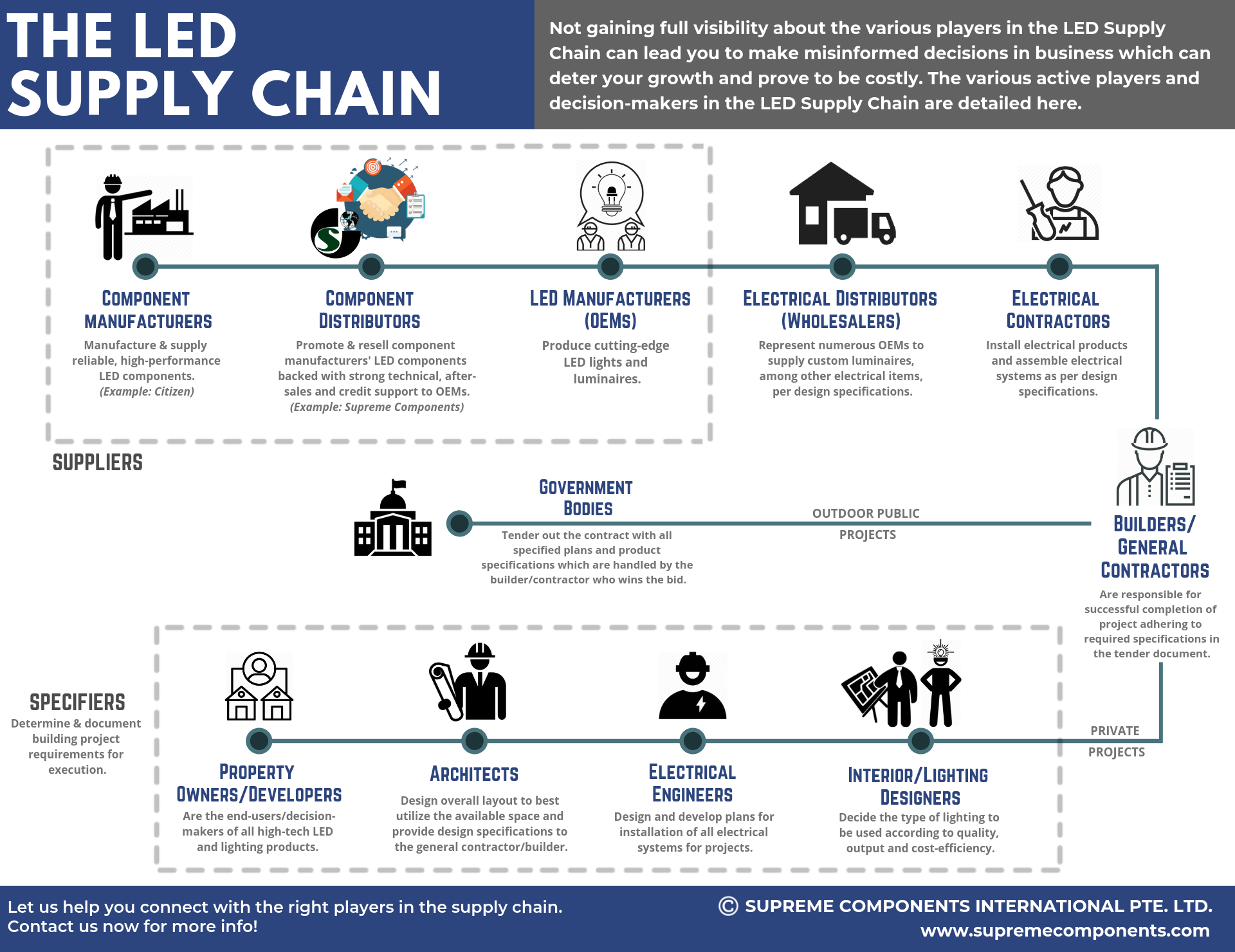

For any OEM manufacturing finished products for either public or private projects, it is crucial to know the nitty-gritties of the LED supply chain (click here to see the entire breakdown of the LED suppply chain).

As a manufacturer, knowing the various tiers of companies operating above and below you can significantly help improve your business and develop a narrative to market your product to the right segment. Knowing the applications and therefore the various specifiers who create demand will also allow you to tailor your products to suit the market conditions.

3. Specifications Mismatch

A complete LED lighting system is made up of several components which are intertwined to produce an illuminating design. Having a hotch-potch of different components could sometimes have undesirable effects in terms of performance, lifetime, and needless to say, undesired costs.

You need a professionally trained supplier to help sort out your actual requirements with minimal hassles. Make sure to test and check whether all the components that would be used in the final lighting system are in harmony with each other, so that you can build a flawless luminaire.

4. Laboratory Testing vs Actual Performance

It is a no-brainer when we say that you need to test out products before you go into mass production for your lighting projects. Testing is absolutely important since the components you purchase need to show their mettle. Considering that amongst LED components, even brightness and color can vary between different components under the same manufacturing batch, testing becomes all the more important.

But often times what happens is that the testing is done under optimal conditions. This would give out results which are tangentially different to what you may experience with the end-product in the application phase. So, lighting professionals should be wary of a tolerance in values between the tested parameters and the real-life equivalent.

5. Choosing a Supplier with No Support

One can only be so safe before purchasing LED components. In an engineering-intensive industry, it is quite normal to assume that you will be granted full support in terms of engineering/product selection or in case of product failures . This is where you can easily distinguish average suppliers from the truly reputable ones.

In most cases, since distributors assume the role of seller, it is natural to expect them to extend full after-sales support to ensure your product development lifecycle is complete without any hurdles. But the reality is far from true since many distributors lack the technical acumen/personnel to attend to these requests and are caught up trying to liaise with the suppliers to help with support. Or worse, just ignore you.

On the other end of the spectrum lie distributors like Supreme Components International (SCI) who have full-fledged customer service and product/engineering teams and provide end-to-end support. SCI assists you right from the design-in stages to helping you enter mass production as well as ensuring complaints (if any) are resolved at the earliest. As a distributor putting the customer ahead of everything else, SCI also ensure a seamless warranty claim procedure so that it does not impede your manufacturing process.

If you think there's something amiss in your LED world, do reach out to us at hello@supremecomponents.com and we can work out a complete solution!